The product Engineering works in co-design with the customers to optimize dimensions, tolerances and technical specifications of the finished parts.

In accordance with APQP system, the process engineering is responsible for the products industrialization from prototypes, S.O.P of the serial production and ramp-up to full volume.

A skilled technical Team plans the production processes, the lay-out of the equipment, prepares the technical documents, the CN-CAD-CAM programs and the control-plans.

Quality

Quality

It ensures the quality of the incoming goods, on the internal operations and on the selling products, applying all the quality procedures and standards. By focusing on continuous improvement and on the World Class Manufacturing Method, the aim is to reach “zero defect”.

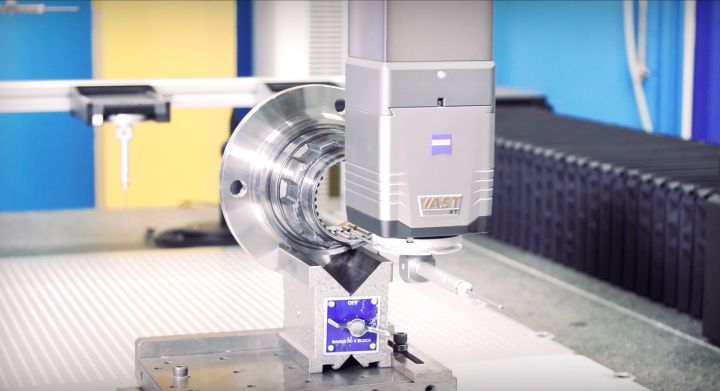

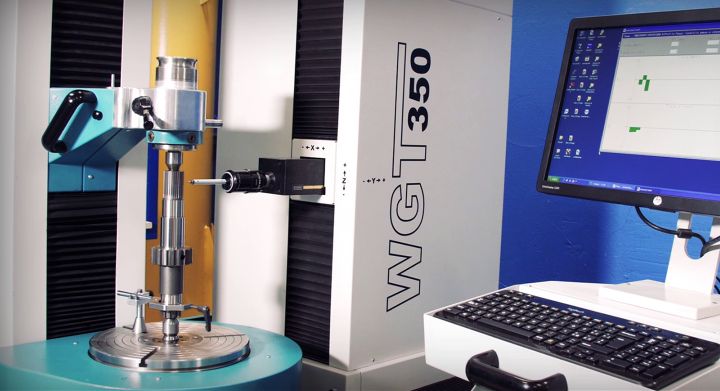

Internal Processes Control

Internal Processes Control

It verifies and studies processes and products, inspecting activities, reaction plans, maintenance of certification procedures.

Programming of Methods

Programming of Methods

It analyses and optimizes the individual stages of our production. It organizes productive lay-out and the material flows.

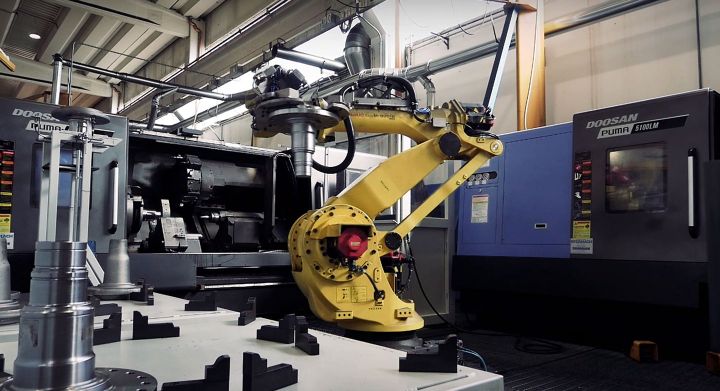

Machinery and Prototypes Dept.

Machinery and Prototypes Dept.

It retrofits machines and supports the manufacture of prototypes